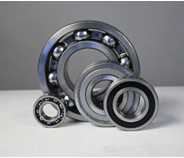

Single Row Deep Groove Ball Bearings

Ball bearings are so called because they have balls as rolling elements. The load is transmitted from the outer race to the ball and from the ball to the inner race. Since the ball is a sphere it only contacts the inner ring and outer ring at a very small point, which minimizes friction and helps the bearing to rotate very smoothly. This also means that there is a minimal contact area supporting the radial load therefore if the bearing is overloaded the balls can deform and the bearing will fail. More information & Dimensions